Agilent Technologies Inc.

Agilent’s recent initiatives ensure that its entire staff is moving toward the same goals.

By Alan Dorich, Senior Editor at Knighthouse Media

Every time Agilent Technologies Inc. serves a client, it has the goal of achieving a greater good. “Every product we make – no matter where we are – makes this world a little better every day,” Henrik Ancher-Jensen says.

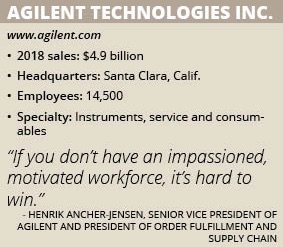

Ancher-Jensen is the senior vice president of Agilent and president of its order fulfillment and supply chain (OFS), a 3,000-person team that shares this vision. “There’s a lot of passion around what we are doing,” he says. “If you don’t have an impassioned, motivated workforce, it’s hard to win.”

Santa Clara, Calif.-based Agilent provides instruments, services, consumables, applications and expertise to laboratories worldwide. The company was born in 1999 as a spinoff of Hewlett-Packard Co., building electronic measurement instruments and other equipment.

In the last five years, Agilent spun off that part of its business and refocused on life sciences, cancer diagnostics and genomics. Its products now include highly advanced equipment such as gas and liquid chromatographs and mass spectrometers –- instruments that are used in the most cutting-edge research around the globe. Today, “We deliver almost anything you can imagine in an analytical lab,” Ancher-Jensen says.

Agilent’s markets include environmental and forensics, where it provides methods to monitor contaminants affecting quality of life. For example, the company provides tools to measure the cleanliness and safety of drinking water.

Agilent also helps the food market ensure that products are free of contaminants. It also provides solutions to the pharmaceutical industry and helps the diagnostics market fight cancer and other diseases. “We want to be No. 1 in every single market where we compete,” Ancher-Jensen says.

Making Changes

Since it spun off its electronic measurement business in 2014, Agilent has focused on restructuring its supply chain and manufacturing. As part of this process, the company created four Centers of Excellence (CoE).

One focuses on instrument manufacturing and the second specializes in bioreagents. The third focuses on chemicals, and the fourth performs broad-based logistics functions.

By developing these four CoEs, Agilent has streamlined its processes and operated more efficiently and with less cost. “I like to think we could continue to do that for a while,” Ancher-Jensen says, noting that the company always looks at ways to create additional value.

This included the creation of its OFS Academy, an online school to help iemployees better understand what it means to be in a supply chain. “We have taken about 200 people through a mini-MBA in supply chain so they understand how everything fits together, and can have an un-siloed view of what they do every day,” he says.

This helps Agilent’s employees understand that if they do not do their own jobs well, “The next person in the chain is going to have an issue,” he says. The company also focuses on making sure its people are moving toward the same goal.

“You can have all the strategies in the world, but you have to make sure that everybody’s walking in the right direction,” Ancher-Jensen says, noting that it used the OFS Academy to quickly and effectively launch its global and supply chain strategy to thousands of employees around the world.

“We built a platform where we involved all of our leaders worldwide in a strategic activation sprint,” he recalls, adding that this helped Agilent’s staff understand what it was trying to accomplish. “We now have people in the mode for getting upgraded.”

Doing More with the Same

One major focus of Agilent’s initiatives is to do more with the same number of resources. “The way I have positioned this to our team is, we need to come up with a way to serve double our current demand with the same number of people,” Ancher-Jensen says.

This led to the creation of Agilent’s “OFS Future Lab,” a website where an employee can contribute ideas on how to use megatrends such as artificial intelligence. “We have a number of incubators where people think about what we are going to do with artificial intelligence scenario planning or things like that,” he says. “Hopefully, by doing this, we will be able to curate ideas that we can incorporate into strategic processes.”

Another megatrend Agilent is studying is general automation. “We spend a lot of time and effort working on finding the best ways to help our employees use these new technologies,” he says, noting that the OFS Academy recently added an OFS School of Digital Innovation.

This online curriculum is specifically curated so employees can become more knowledgeable about the technologies that will be important to Agilent for years to come. “The idea is to demystify these,” he says, noting that the OFS Future lab has been very successful, with employees having submitted several hundred ideas in the last few months.

As an example of how well Future Lab is working, Agilent initially did not think it had many employees who knew a lot about artificial intelligence. “It turns out we had quite a few, and we now have many of these folks collaborating together in the community,” he says.

Ancher-Jensen sees a strong future for Agilent with its forward-thinking approach toward leveraging new technologies and true employee engagement. “If we do that right, we can ensure our value creation engine keeps running for many years to come in such a way that our customers, employees and shareholders continue to benefit,” he says.