Brooks Automation

Brooks Automation’s logistics team adopts lean practices and tackles challenges resulting from new tariffs on China.

By Kat Zeman, Senior Editor at Knighthouse Publishing

With the United States imposing new tariffs on Chinese imports, Donna Poole and her logistics team at Brooks Automation have been implementing new processes to combat some of the challenges that the tariffs pose on the company’s supplier relationships. “We have major suppliers in China,” says Poole, Brooks Automation’s senior director of global logistics and trade compliance.

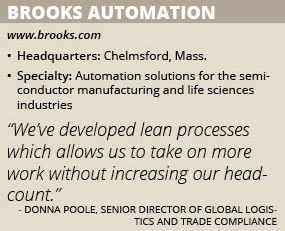

Her small team of five people handles all transportation, distribution, warehouse and import/import export logistics solutions for Brooks Automation, a global leader in automation solutions for the semiconductor manufacturing and life sciences industries.

Based in Chelmsford, Mass., the company has operations in North America, Europe and Asia. It applies its automation and cryogenics expertise to provide a full suite of sample management solutions across life sciences to enable areas such as drug development, clinical research and advanced cell therapies.

In addition, Brooks Automation recently added global capability for genomic services to its life science portfolio through its strategic acquisition of South Plainfield, N.J.-based GENEWIZ. Founded in 1999, GENEWIZ services more than 4,000 institutional customers worldwide and is supported by a global network of laboratories spanning the United States, China, Japan, Germany and the United Kingdom.

In order to combat challenges associated with the new tariffs on China, Poole and her team have initiated a duty drawback program, an export promotion program intended to eliminate and recover the costs of duties, taxes and fees on merchandise sold on international markets. It is one of the few export incentive programs acceptable under World Trade Organization rules.

“It’s a pretty intense program to put together,” Poole says. “There are a lot of checks and balances and you have to cross all your T’s and dot all your I’s.”

Brooks Automation submitted its application in March and hopes to be approved by December. As an increasing number of companies are applying for the program due to the new tariffs, it takes an average of nine months to be approved.

A Diverse Portfolio

Brooks Automation is known for its diverse portfolio, which has been growing at a fairly rapid pace. Since 2011, the company has undergone 15 acquisitions – 11 of which were in the life sciences.

“With 15 acquisitions, we are now in a lot of different countries,” Poole says. “It’s been a challenge for a team of five people to manage everything from setting up shipments to negotiating contracts but we adapt really well. We can accommodate the additional workload by streamlining our processes and we’ve developed some lean processes which allows us to take on more work without increasing our headcount.”

For example, when dealing with Brooks Automation’s brokers, the company has implemented a system that eliminates the need for brokers to ask repetitive questions during each encounter.

“We put together business rules for that broker, so that they don’t ask us that question again,” Poole explains. “Each question could take three minutes to answer. So, that one small change saves us a lot of time.”

Service Providers

Poole and her team also manage logistics service provider relationships. When selecting logistics service providers, the team looks for customer-focused providers.

“We are cost-driven, however, the expectation of Brooks is that the service provider acts as an arm of our organization,” Poole says. “If a service provider offers a cost-effective rate but can’t back that rate up with excellent customer service/support, they wouldn’t be selected as a logistics partner for Brooks Automation.”

The company partners with very select companies like FedEx, Expeditors and Yusen Logistics because of their ability to service its accounts effectively and with great customer service, she adds.

“Our expectations are high and they need to be so we can service our customer’s high expectations,” Poole says. “We need our service providers to watch our shipments and proactively communicate any challenges they are facing.”

With thousands of shipments moving each month, Poole’s small team would not be able to track every shipment. “Our logistics providers need to be our eyes,” she says. “I guess you could say we build true partnerships with the suppliers that are willing to go the extra mile for us.”