Matthews Automation Solutions

In control

Agile, innovative and growing, Matthews Automation Solutions provides the software and controls behind warehouse automation for some of the world’s biggest brands

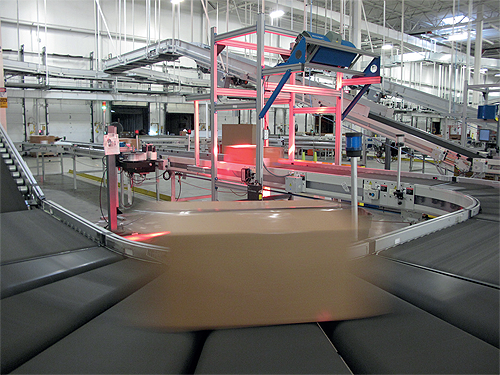

For over two decades now, major global corporations have been partnering with Matthews Automation Solutions for its innovative material handling technologies and proven vertical industry expertise. A member of Matthews International (MATW), the company provides advanced software and controls to the warehouse automation industry, and its software solutions can be found in distribution centers and ecommerce fulfillment facilities worldwide.

Made up of the warehouse automation brands Compass Engineering, Lightning Pick and Pyramid, Matthews connects automated systems into one centralized stream, balancing work throughout the fulfillment process for optimum material flow, efficiency, accuracy, real-time visibility and speed. Compatible with any mechanical system, and combinable with emerging collaborative robot technologies, Matthews’ solution architecture is built to meet the process challenges of  today and tomorrow.

today and tomorrow.

“At Matthews Automation Solutions, software and controls-based technology are our expertise, whereas at some mechanical automation companies they often take a back seat to mechanical products,” explains Gary Cash, the company’s General Manager and Vice President. “The differentiator is our warehouse execution software. We compete by offering more comprehensive feature sets than our competitors.

“As an overview, our systems help control operations at a distribution center – managing flow, releasing, fulfilling and shipping orders,” Gary adds. “As part of that, we specialize in fulfilment systems and technologies that pick and pull units from where they are stored and place them into orders. Along with our superior software, we are not tied to any brand of conveyor or storage system, meaning we are agile enough to grow with a changing business.”

Matthews’ success stories include a decade-long partnership with a worldwide shoe retailer. Having first installed controls and software at the company’s 1.8 million square foot California site, Matthews has grown with the business as it moved overseas, installing new systems for the retailer in Belgium and China.

Productive long-term partnerships have been a Matthews hallmark throughout its history and the company continues to value collaboration today. In 2018, Matthews partnered with a leading meal-kit provider, adding semi-automatic systems and software into its US facilities to help with the boxing of ingredients. Since then, Matthews has watched the meal-kit company grow across California, Texas, Georgia and New Jersey, applying different automation solutions on a case by case basis to help reduce lead times and break into new markets.

“At one time or another we’ve worked with almost every integrator in the industry because we strive to be easy to work with for both integrators and customers,” Gary declares. “Typically, these companies will provide the mechanical scope and installation, whilst we will provide the software and controls portion of the solution.

“Our best partners are the ones who bring us to the table early on in the process and let us help design the system because they recognize the importance of the software. It means we can work together between mechanical, controls, software, and the end user to build a system that fits the client.”

One of the key factors behind Matthews’ longevity and continued success is the company’s willingness to understand that each customer possesses its own culture and requirements, and therefore, there can be no ‘one size fits all’ approach to its solutions. Instead, Matthews employs a more flexible, tailored methodology in its projects, and at the heart of this lies a focus on innovation.

“Innovation is one of those topics that is becoming more and more important on the software side because we control how orders flow through a building. The smarter we can be with optimizing flow – anticipating when there is going to be capacity, making sure we don’t overflow the system – the better the solution is going to be,” Gary says. “A lot of our customers have one million square foot buildings, yet by using technology we can know how busy every area of a building is at any one moment, so we can anticipate capacity and release work.

“Algorithms, adaptive analytics and machine learning all play a part, but in simple terms, our systems maximize customer success. They are there to make sure that, even on your busiest day, you are doing everything you can to stay efficient.”

Though Matthews’ work is inherently centered around software and machinery, the company is also reliant on a highly skilled technical team, committed to learning about and understanding the latest technology in a rapidly changing market. Of course, many of Matthews’ employees have been forced to work from home over the last 12 months as Covid-19 restrictions led to a reduction in staff onsite. Gary suggests that this wasn’t the only impact of the pandemic.

“There was a three-month period where new orders went way down and some were even cancelled, but by September, things picked up and we ended up achieving a record year for new orders,” Gary reveals. “When we heard that customers were having trouble keeping product on the shelves, it became obvious that it in a crisis environment it is important to keep up with demand. A noticeable trend was an increase towards ecommerce. Once companies saw the benefits of that change in consumer habits, they started placing orders with us. They realized that they needed to be more aggressive and continue investing in their supply chain. Everyone learned together, and right now, this industry is as busy as I’ve ever seen it.”

Before 2020, ecommerce had been an increasing factor behind Matthews’ growth, but the trend was intensified by Covid-19. The company’s experience in helping retailers expand their ecommerce platform proved invaluable during the crisis.

“While many of our competitors were working out ecommerce on the fly, we already knew what had worked well in the past and we were able to apply those fundamentals,” reports Erica Wine, Matthews’ Product Marketing Specialist. “The growth is set to continue well beyond the pandemic. We are now working not only with meal-kit providers but also grocery delivery and pickup services. Even in sectors that were traditionally instore only, people have realized that they can buy more conveniently online.”

With more and more consumers shunning instore for online, the importance of ecommerce to retailers is only going to intensify in the future. Consequently, Matthews is already developing new technology and advanced algorithms that will improve its offering in the months and years ahead.

“It’s funny, when I get in front of customers I ask, ‘When was the last time you received an ecommerce shipment that was wrong?’” Gary remarks. “Almost every time everyone shakes their head, and I tell them that it is due to software like ours. We make sure that the right items are in the right box and that they are going to the right place. A lot of what makes ecommerce possible, and successful, is the software behind it.”

One of Matthews’ newest software products is NEXUS, a warehouse execution solution that takes full advantage of contemporary web-based technology. Compatible with any device, NEXUS will be released later in 2021. Beyond that, Gary believes that Matthews will be looking towards introducing more advanced algorithms as well as solutions that work in cohesion with autonomous mobile robots.

“Our brands Pyramid and Compass have their own software products that are best in grade, but we will soon be jumping to newer technology in order to come out with something that could take over the industry in terms of management flow, building optimization and compatibility,” Gary asserts. “Robotics is growing quickly and is going to take over a lot of operations, so being able to communicate and drive efficiency on that front is a big ambition for the future.

“We have been one of the leaders in warehouse execution software for a number of years and that is where we want to stay. The market is continually evolving and we are doing everything we can to stay at forefront of that.”

Matthews Automation Solutions

www.matthewsautomation.com

Products: Warehouse automation software and controls