Gartner Key Strategies for Driving Resilience in Supply Chain Planning

Brought to you by Gartner Supply Chain Planning Summit.

Companies are trying to make their supply chains more resilient in the face of frequent disruptions. To do this, supply chain leaders need to focus on change, risk management and technology.

According to Ingrid Gonzalez McCarthy, the Gartner Supply Chain Planning Team’s Senior Research Director, these leaders typically rely on a single plan — which makes it tough to adapt when things go wrong. Spreadsheets, although popular, fall short because they rely on manual inputs, have limited data capacity and use static figures, which just don’t cut it in our unpredictable world. Plus, risk management is often hit-or-miss, leading to poor responses when uncertainty strikes.

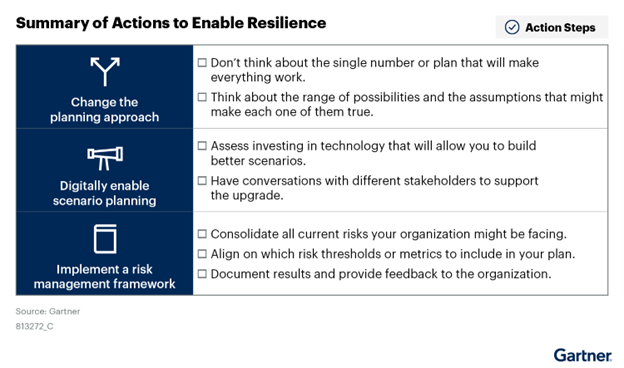

3 actions to build supply chain resilience

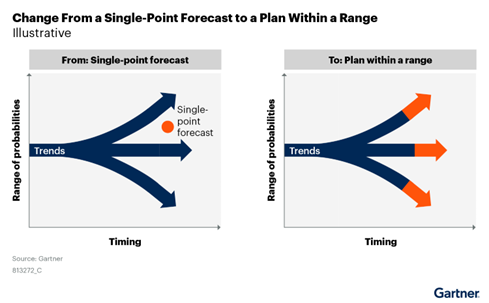

1. Move from single-number to probabilistic planning

Traditionally, supply chain planning has relied on deterministic methods to create very precise plans based on a single forecasted number. However, this approach often falls short when dealing with variability. A better approach is probabilistic planning, which considers a range of possible outcomes to optimize decisions, time, resources and inventory more effectively.

To begin employing this type of planning, leaders can utilize S&OP (sales and operations planning) meetings to discuss potential risks and opportunities, and decide which scenarios to prepare for. This forms the basis of “the range,” which includes the main plan and its probable variations. However, merely discussing these scenarios is not sufficient; organizations must actively define and prepare for them to ensure they fall within the anticipated range.

2. Invest in digitally enabled scenario planning

According to the 2023 Gartner Antifragile Supply Chain Management Survey, more companies are expected to start using probabilistic planning — up by 23% in the next two years. This shift means supply chain leaders need to get comfortable with uncertainty. Reality is always going to land somewhere within the planned range, and some parts of that range might end up being off.

To build resilience, supply chain leaders should embrace dynamic digital scenario planning. This approach is perfect for today’s fast-paced, interconnected world because it adapts quickly to changing conditions and rigorously tests assumptions — something traditional planning just can’t keep up with. Dynamic planning uses digital tools to monitor variables and their interactions, making data management easier and improving responses to emerging risks.

Key elements of digital scenario planning include managing large volumes of data, revising fixed assumptions and handling diverse parameters. This strategy is crucial for identifying trade-offs and figuring out proactive measures to tackle disruptions. Leaders should explain the benefits of advanced planning tools to their organizations, highlighting how these tools enhance resilience and improve decision-making. Implementing these tools involves a significant investment and a change in the operational mindset. To show their value, leaders should start with pilot projects and encourage regular scenario-based discussions in S&OP meetings to refine decision-making processes.

3. Implement a Risk Management Framework

Risk management within planning teams is often inconsistent. The 2021 Gartner Supply Chain Risk and Resilience Survey found that 57% of respondents see a clear need for better defined risk processes and governance. Additionally, the survey noted a 25% improvement in business response effectiveness when a formal risk process is implemented.

To address this, forming a risk committee to oversee supply chain risks is recommended. This committee would monitor assumptions, set risk appetites, and review risks during S&OP sessions. They would also track the effectiveness of risk responses in collaboration with the leadership team.

Supply chain planning leaders should advocate for the creation of this committee, highlighting its benefits with examples of preventable incidents and ensuring involvement from both strategic and operational sectors. Regular assessments of emerging and realized risks should be conducted, with outcomes measured using specific metrics.

Risk management is becoming increasingly complex. Recent surveys show organizations now evaluate risks based on multiple factors, including:

- Impact

- Likelihood

- Interdependencies

- Time to impact

- Volatility

This complexity underscores the need for a well-structured and proactive risk management strategy in supply chains.

Dive deeper at Gartner Supply Chain Planning Summit 2024

Join supply chain planning leaders on the journey to move beyond accuracy and build a future powered by collective value creation at Gartner Supply Chain Planning Summit 2024.

Discover must-have insights, strategies and frameworks designed to help you and your supply chain leader peers think big, make bold moves and drive real impact within your organization.

14 – 15 October 2024 | London, U.K.