How Vapormatic has become a leading replacement agricultural parts supplier

Vapormatic was founded by Arthur Lea and Ron Foster in 1949. “The pair saw an opportunity for a product that could help combat issues arising from the post-war fuel shortages. Ron Foster had designed a vaporizer manifold that converted agricultural engines to run off vaporizing oil,” explains Zoe Ashby, Managing Director of Vapormatic. “As engines and fuels evolved, Vapormatic diversified its product range, eventually growing into the leading range of alternative parts for all makes of tractor.

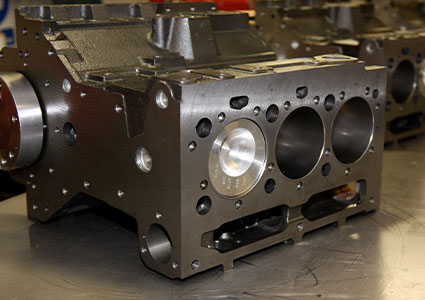

“The specialism that Vapormatic is now known for,” Zoe elaborates, “is the engine portfolio. We are seen by many customers as a technical partner. They recognize not only the quality of our parts, but also the services we provide. For example, as well as providing the highest quality pistons or crankshafts we also offer pre-built short motors, which is an engine block already fitted with everything it needs to be ready to fit into an engine. This is something that can save our customers significant amounts of time.

not only the quality of our parts, but also the services we provide. For example, as well as providing the highest quality pistons or crankshafts we also offer pre-built short motors, which is an engine block already fitted with everything it needs to be ready to fit into an engine. This is something that can save our customers significant amounts of time.

“The strength of the product is such that we can offer a full 12-month warranty which includes not only the cost of the product, but any time taken to make the repair. While engines may be what we are best known for, we also offer a very broad portfolio of products that include full ranges of accessories, PTO, hydraulics, trailer and combine parts, paints, plus radios, camera systems and immobilizers.”

Farmers of the future

In celebrating its 75th anniversary Vapormatic is not only reflecting on a long and successful history but also looking ahead to the farmers of the future. “In collaboration with the local agricultural college,” Zoe explains, “students are supporting the restoration of a Fordson Dexta tractor to its former glory for auction, with all funds raised going to Force Cancer Charity.” More than just a one-off association, this is an ongoing relationship the company is proud of. “We support the local colleges in any way we can whether that be supplying parts for rebuilds or work experience opportunities.

“The business is also active in the global agricultural community, partnering with the Bicton Overseas Agricultural Trust, which works with farmers and agricultural leaders to provide education on land management and machinery maintenance. Over the last 20 years we have supported them with over £200,000 worth of parts and fundraising.”

This conviviality is representative of the business’ broader approach to its relationships. “In placing such an emphasis on the quality of our products, having positive and long-term relationships with suppliers is crucial,” Zoe explains. “Developing a product to our high standards can be time consuming and development often requires revisions and improvements before a part is ready. Repeating this with multiple suppliers would quickly become unsustainable.”

With environmental concerns ever present in agricultural sectors around the world, Vapormatic is also ensuring its impacts are minimized wherever possible. “As well as working with the environment agency, who are situated on the same industrial estate, on tree planting initiatives, we have installed solar panels on the roof to make the most of our own resources. We are also implementing more sustainable packaging to reduce our plastic usage,” Zoe adds. This is alongside an industry-wide push to make agricultural machines less impactful and more efficient, a development on which Vapormatic is poised to capitalize. “We’re always looking at that as an opportunity,” Zoe explains. “As well as more efficiency, there is a demand for more automation. Whilst we’re not at the sharp end of producing those high technology machines, we are in the business of providing parts and services to support them, therefore, our portfolio needs to keep pace with those developments.”

Preparing for the next 75 years

In addition to making sure its product portfolio is up to date, Vapormatic is also in the process of implementing a new enterprise resource planning system, which will make operations significantly more efficient. “The system will bring end-to-end improvements throughout the whole business, enabling us to provide a better service to our customers,” Zoe says.

In addition to making sure its product portfolio is up to date, Vapormatic is also in the process of implementing a new enterprise resource planning system, which will make operations significantly more efficient. “The system will bring end-to-end improvements throughout the whole business, enabling us to provide a better service to our customers,” Zoe says.

“The business has also invested heavily over the last two years, working with a partner to provide overnight delivery to our customers,” Zoe expands. “We have also restructured our warehouses to improve logistics. In agriculture, jobs need to be done when they need to be done, so downtime can be incredibly frustrating. Improving our logistics and supply chain side of the business means that our customers can get the parts when they need them.”

Part of this improvement emerged because of the global issues the supply chain has experienced in recent times. “We’ve had to put more inventories in place, so in 2021 we opened a second warehouse,” Zoe explains, “this gives us much more of a buffer against disruptions. Whether they’re caused by Covid or the Suez Canal, we are now able to mitigate against them.”

These improvements are part of a swathe of bold plans for the future which include, “updating the website to improve the experience for the end-user, as well as investing in a greater global footprint and logistics infrastructure to better support our global customers. It will also be key in the coming years,” Zoe continues, “to make sure we can offer farmers the right products at the right prices. For several years input prices have risen, the cost of labor, fuel, fertilizer, and seeds have all increased. Developing parts for more efficient and sophisticated machines that can mitigate some of these costs will be essential.”

Celebrating its 75th anniversary, Vapormatic is well positioned to take on the next 75. With operations across 80 different countries, a modernized supply chain and logistics infrastructure, and positive and long-standing supplier relationships, the business has the opportunity to expand further into global markets.