Sonic Manufacturing Technologies Leads the Digital Supply Chain Revolution in Electronics Industry

Let’s get digital

Big things are brewing at Sonic Manufacturing Technologies as the company announces the arrive of the digital supply chain

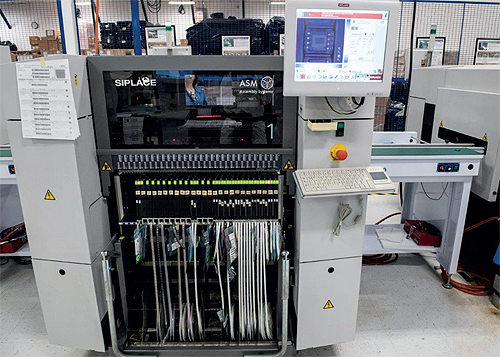

Sonic Manufacturing Technologies has pioneered the electronics industry with its innovative transformation into a fully digital supply chain, despite a tricky year for the technology sector. Specializing in electronics manufacturing services (EMS), Sonic provides PCB layout, prototyping, new product introduction and production at scale; and has taken its core processes to new heights.

David Ginsberg, Vice President of Supply Chain for the company, updates us on the commitment to digital that the company has demonstrated since we last spoke with them in 2018, and how this leading-edge tech has accelerated Sonic to the forefront of Silicon Valley manufacturing. “2020 was particularly difficult, but we were fortunate to be classed as an essential service because we supply equipment to hospitals and medical labs. On top of that, the pandemic influenced a lot of work and opportunities that were headed offshore to be built locally, so we took on new customers and new products, and will manufacture these products longer before customers might consider an extended global supply chain again,” he tells us.

on new customers and new products, and will manufacture these products longer before customers might consider an extended global supply chain again,” he tells us.

Along with navigating the ever-changing Covid-19 landscape, Sonic has become the first company to introduce a fully digital supply chain in the electronics industry. According to David, its capabilities successfully automate the supply chain from start to finish: front-end data cleansing logic, accurate material requirements planning (MRP) processes, calculating and processing supply availability against demand requirements, all the way through to managing and validating shipping dates and invoices. “It’s now a complete digital cycle and handles as high as 75 per cent of the one million parts per week coming into the factory,” he informs.

This is a game-changer that increases efficiency, agility and responsiveness. “Digital is a bit counterintuitive. It is less about presenting ever more data and analytics to people and more about presenting ever more of your mind’s capacity for decision making to the computer. Now with Digital, the planning and ordering process moves in seconds or minutes, rather than running it through a one or two-week procurement cycle. So, if 75 per cent of the parts are ordered within a minute or two after the MRP, then it’s really only the exceptions that move into purchasing,” David elaborates. It goes without saying that there is simply no way for human beings to move at this speed. But since people manage the exceptions, and a smaller amount of work needs to be assigned to each person, each employee now has the time to apply their expertise, skills and knowledge to solving unique issues. “They’re now dedicating their talents to problem-solving, rather than simply calling up the supplier of record and placing repeat orders, which the computer does very well. Job satisfaction goes up, boredom from repetition goes down. Honestly speaking, having this much of the organization focused on exception management and problem solving has been transformational for us,” highlights David.

As the topic of Digital becomes more prevalent in industry, a pressing concern is the effect it will have on the necessity of human jobs. However, David notes that the way in which the digital supply chain is designed demands human action. This is because a level of trust has to be invested into relationships where computers are ‘hard-wired’ into each other for data-sharing. “Any time you do integrations like this, there’s a degree of stickiness between both parties, which means that the company and personal relationships tend to be long-term; while for exceptions and problem-solving, knowing your partner is equally important,” David says. In his opinion, it is vital to prove to suppliers that strengthening digital relationships is as financially in their interest as it is for the buyers. Sonic’s integrated partners, using application programming interfaces (APIs), have seen increasing proportions of Sonic’s business in their revenue, and they process orders to invoice at ever lower costs. “Digi-Key was our first partner, and we now have about 12 live connections to most of the major US electronics distributors.”

Even within the company, the digital development is in no way sacrificing its people for the success of digital progress. “Going digital has not cost anybody their job and that result is deliberate. Learning to work interactively with a digital supply chain is a whole new and valuable job skill,” David continues. Rather than replacing people, this process is about performing better organizationally to provide a higher level of customer service at a faster speed and a lower total cost. In his example, he says: “Think about a printed circuit board with 100 different components on it. If the APIs and stock suppliers we’re working with are capable of bringing in 92 parts on time, that means that I would have eight exceptions. Without getting those eight  exceptions into the building, the product would just sit there, waiting for those last parts to arrive before it could be built and shipped. The faster you move the supply chain, the more exceptions there are to manage and therefore the need for more exception managers, not less. There will never be a time when automation replaces 100 per cent of the parts coming into the building; so relationships matter.” This clearly shows that, contrary to popular belief, capable problem-solvers remain crucial to the digital supply chain.

exceptions into the building, the product would just sit there, waiting for those last parts to arrive before it could be built and shipped. The faster you move the supply chain, the more exceptions there are to manage and therefore the need for more exception managers, not less. There will never be a time when automation replaces 100 per cent of the parts coming into the building; so relationships matter.” This clearly shows that, contrary to popular belief, capable problem-solvers remain crucial to the digital supply chain.

Although digital has already achieved many benefits for Sonic in the electronics industry, Sonic is determined to continue to lead the industry in digital supply chain; and looking into the rest of a difficult 2021, its main goals are twofold. First, by rolling out more transactions with more suppliers, improved performance and revenue growth becomes part of the ongoing digital transformation. David would love to implement more transaction sets with his suppliers. “Being involved in these conversations and working with the right supplier teams to offer additional API capabilities fosters an environment where this will happen organically, and it also means that the evolution of digital capabilities will perpetually increase in sophistication,” he highlights. From here, Sonic can only go up.

Second, the past 12 months hit the electronics market brutally; prices are higher and parts are harder to come by, which means there are challenges in both their pursuit and the management of the business. “My head-scratching for this allocated and constrained market is in how much leeway to give the computer on purchasing higher-priced parts, and how much of that should go to a human expert. If you give the computer too much authority to spend money, you’ll inevitably go out of business, but if you put too much work on your staff’s plate, they can no longer work effectively on solving each individual problem,” David tells us. “The lower cost of digital can compensate somewhat for the higher cost of materials in this marketplace. Beyond speed, accuracy and volume, we can frequently buy constrained parts before our competitors, or even our own staff, know of their availability.”

As David explains digital transaction costs, whenever the computer completes a transaction, a buyer did not need to complete this exchange, while on the supplier’s end, an inside sales person did not manually process it, and the costs to both parties go down. “Speed and accuracy go up as well because it’s a computer transaction that doesn’t make typos, forget a step or run out of time; making everything about the process improve,” he continues. “People therefore evolve from transacting the routine to solving the difficult.”

In a way, the company has managed to hack the digital supply chain with just two programmers, David and supply chain engineer Niyati Patel. They have achieved results that larger, more expensive IT teams have yet to achieve during the same period. “We do all the SQL programming in house and work with Orbweaver for the API integration and transport.”

David is determined to share Digital Supply Chain with the industry for the success of other businesses. “What I’ve always wanted to convey to the industry is that the digital supply chain does not have to be a large and complex consultancy-oriented project. At its core, it is very intuitive and emulates how you’re already doing business,” he emphasizes. He adds that the entire transaction choreography of the existing phone call or email exchange of a buyer with a supplier can easily be duplicated in APIs, meaning there is no need to invent new logic to automate the supply chain process. The customer requests supplier data, compares it to internal demand and schedule, then applies existing procurement rules for cost, quantity and delivery that are based on how an existing buyer or planner would decide. The ‘passing’ data is sent to a digital purchase order for transmission; exceptions are routed to humans. “I hope to offer some classes or industry presentations later this year to coax people down this path.”

By paying attention to detail at the level of data quality and transactions, Sonic has achieved demand-driven manufacturing efficiencies and is championing the future of the digital supply chain revolution. “We’ve been able to build this with zero budgeting in just a few years and we are fully convinced that this is the right way for the industry to go because the results are immediate and substantial. Customer service goes up, costs go down; Agility and Responsiveness are achieved without ever having been a standalone metric or project team,” David concludes.

Sonic Manufacturing Technologies

www.sonicmfg.com

Specialty: Electronics manufacturing services provider (EMS)