Zero-Touch Tech from Locus Robotics Boosts Picking and Efficiency

Subscribe to our free newsletter today to keep up-to-date with our latest supply chain news.

Rising consumer expectations, volatile supply chains, and ongoing labor shortages are forcing fulfillment centers to rethink how they operate. In this environment, the concept of zero-touch order fulfillment has gained traction.

Unlike traditional systems that rely on workers walking warehouse aisles, zero-touch solutions use robotic platforms and automation software to complete orders with speed and precision.

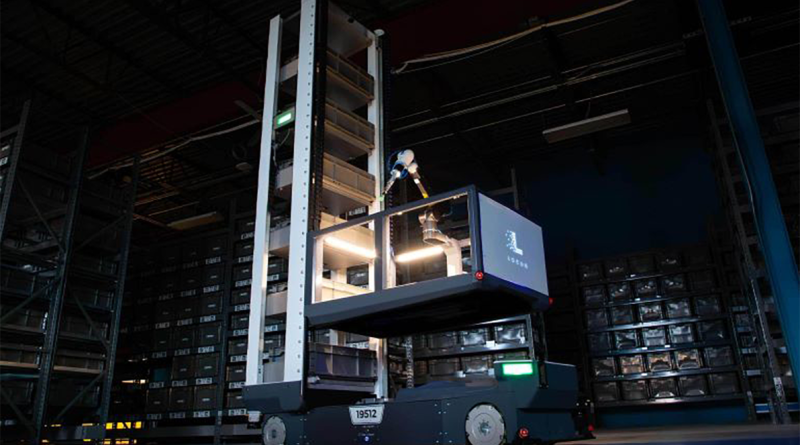

Locus Robotics has entered this space with its latest innovation: the Locus Array. Designed to support high-density order picking with no manual touches, the system introduces a level of automation that redefines how distribution centers can function in high-volume environments.

The rise of AI-driven warehouse automation and its expanding role

Warehouse automation has come a long way from conveyor belts and fixed-path robots. Today, intelligent software, mobile robotics, and adaptive algorithms are redefining fulfillment operations. These systems are no longer just tools; they operate as integrated components of day-to-day workflows.

Artificial intelligence enables real-time coordination across robots, orders, and inventory systems. In the case of the Locus Array, AI manages the motion of robots and directs picking, placement, and replenishment based on continuous data from the warehouse floor.

One of the advantages AI offers is adaptability. While older automation systems often required custom infrastructure and long implementation timelines, the Locus Array is designed to be rapidly deployed and adjusted as business needs evolve.

A recent report by LogisticsIQ projects the warehouse automation market to exceed $70 billion by 2027, with much of that growth driven by robotics and AI. Companies under pressure to meet tight fulfillment windows while maintaining profitability are turning to automation as a solution.

Locus Robotics has already built a reputation with platforms like the Origin and Vector. The new Array system extends that ecosystem by targeting high-throughput zones, adding density and efficiency in environments that must scale quickly.

Unveiling the Locus Array system and what makes it different

The Locus Array is purpose-built for fast-paced, high-volume fulfillment environments. It delivers zero-touch picking through a network of autonomous mobile robots, intelligent shelving, and adaptive orchestration software.

At its core is a dense storage layout that uses double-deep shelving to increase inventory volume without expanding the warehouse footprint. The modular design allows for phased deployment, giving facilities the flexibility to upgrade without major construction.

According to Locus Robotics, the system can process up to 10,000 orders per day depending on layout and configuration. Robots handle every step of the process—from tote retrieval to delivery at packing stations—without requiring human intervention.

A major differentiator is the seamless integration with existing Locus platforms. The Array works alongside the Origin and Vector systems, allowing operations to balance volume picking with complex fulfillment needs. This interoperability supports both new installations and retrofits in brownfield sites.

The system’s AI engine continuously adjusts task assignments to reduce traffic, avoid delays, and prioritize urgent orders. Warehouse operators can track performance through a centralized dashboard, streamlining oversight and enabling data-driven decisions.

Deployment time is another key advantage. While traditional automation systems may take a year or more to go live, the Locus Array can be operational in under 90 days. That kind of speed is a competitive edge in a market where agility often determines profitability.

Early deployments of the Locus Array show promising results. Warehouses using the system report improved order accuracy, higher throughput, and better space utilization. Because robots handle picking and transport, manual walking time is reduced, which helps improve worker safety and lower fatigue.

Sources: